How to efficiently Automate your Meal Kitting Operations

How to efficiently Automate your Meal Kitting Operations

Meal kit food delivery services are becoming more popular and have experienced significant growth in recent years. Especially 2020, the year of the global Covid-19 pandemic, has led to a sharp rise of meal kit service providers and a high demand for such cooking alternatives.

City skyline

Afterall, it makes perfect sense. Time is always of the essence and there are several benefits that come with meal kits:

- Fast and easy to prepare, thereby giving us back precious time

- Healthy food dishes that support a healthy lifestyle

- Competitive pricing compared to traditional grocery shopping

- Great variance in dishes and meals

Consumers enjoy speed and convenience, and meal kit solutions go hand in hand with the on-demand economy. However, while sales are up, the business model of preparing meal kits is less profitable. This is due to a combination of logistical challenges:

- High fulfillment cost – very labor-intensive picking process

- Significant demand fluctuation

- High cost for last mile delivery

- Storage and handling of fresh and frozen products needed for meal kits

- Warehouse space and operational efficiency

Most commonly, meal kitting operations are manual. The current operations are based on a pick and pass fulfillment model, following the person to goods principle. This limits order fulfillment efficiency as pick rates max out at 80-100 units/h per operator. Furthermore, to be successful, meal kit providers have to offer a wide range of meals and ingredients, which directly increases SKU count and requires more storage capacity. Simply put, manually fulfilling meal kits is not efficient and can’t keep up with growth and demand.

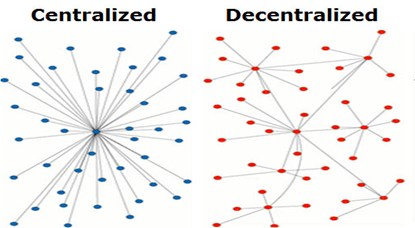

In conclusion, if person to goods is inefficient and flow rack storage is sub-optimal, why not introduce an automated system solution that enables goods-to-person picking and provides high storage density?

City skyline

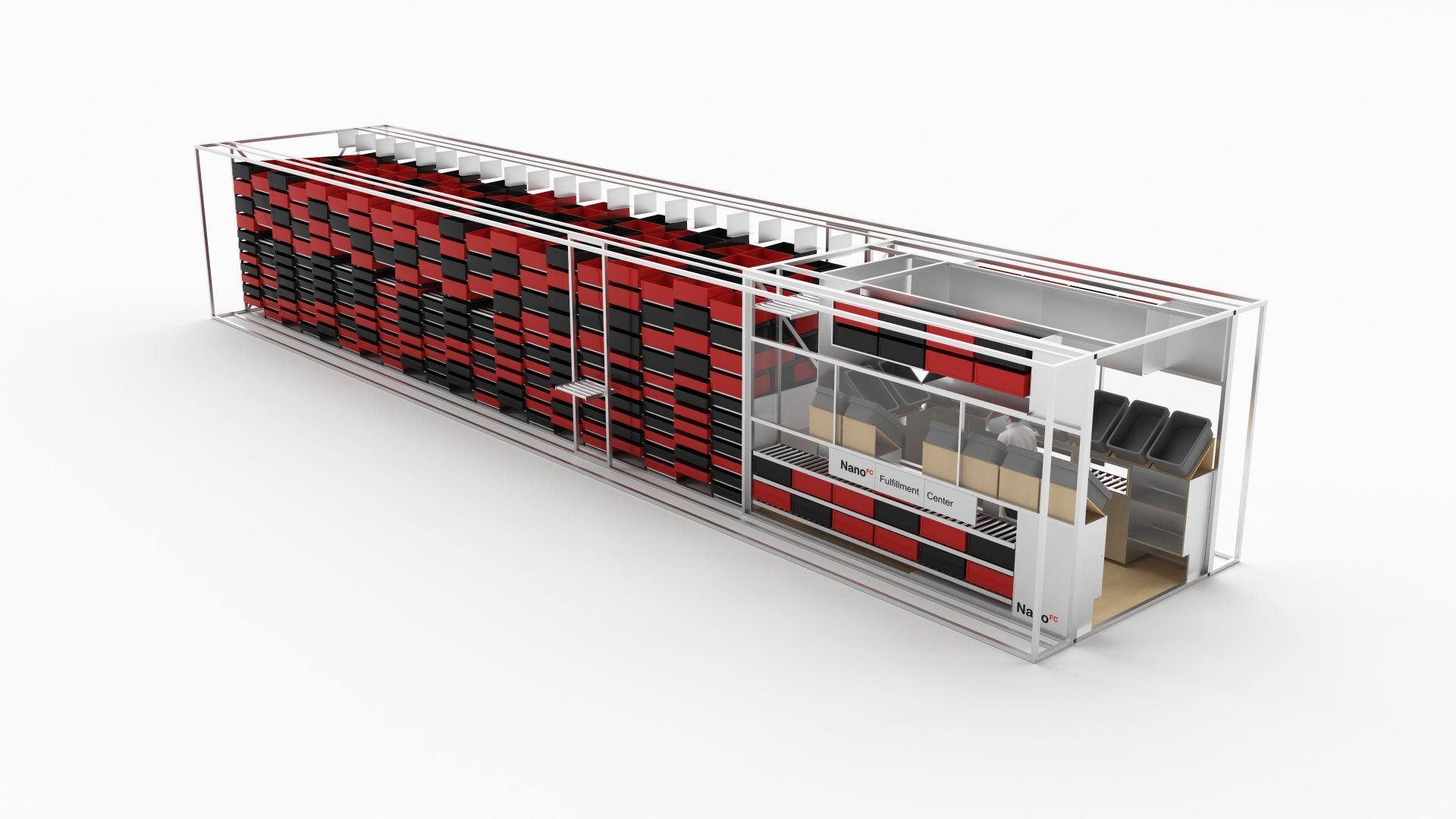

Nanofulfillment® combines both goods-to-person picking and automated storage. It’s the perfect solution to make meal kitting operations more profitable:

- Improves picking productivity by 400%

- Significantly reduces storage capacity and can hold up to 1,000 SKUs

- Requires only 800 SF and 10’ ceiling height

- Operates in ambient and refrigerated temperature zones

- ROI < 2 years

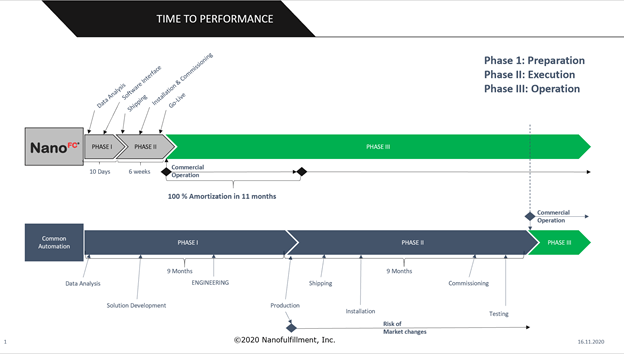

Nanofulfillment® significantly reduces order fulfillment cost, thereby increasing profitability. And our NanoFC® is scalable and re-deployable, which makes it easy to keep up with future growth while keeping the initial CapEx or monthly OpEx low. This turn-key solution is installed and operational within 1 week and can be re-deployed at any time.

It’s time to think outside the box and add value to your meal kitting operation – Get your NanoFC® today!

Nanofulfillment® – Enabling the world’s transition to an on-demand economy