The Underestimated Challenges of Warehouse Automation

The underestimated challenges of Warehouse Automation

In our modern supply chain era, warehouse automation has become a fundamental cornerstone of any distribution operation. Automation offers; process optimization, increased productivity, operational profitability and also a more efficient use of labor. While the benefits of automation are apparent and appealing, the hidden challenges are often underestimated.

Automated systems for warehouse operations, compared to more traditional operations based on manual labor models, have a much higher level of complexity, making the successful installation of such systems very demanding. Contrary to the common perception of being a simple “plug and play” solution, automation has been a very sophisticated combination of technology and highly optimized processes. When not managed well, these systems quickly underperform, cannibalizing production and profitability targets while disappointing even the most loyal customers with low quality, multiple box shipments etc.

What you hear when considering automation is:

- Optimization of space usage

- Higher inventory management and order fulfillment accuracy

- Reduced labor requirements

- Improved throughput and productivity

What you typically will not hear are the ongoing challenges of automation:

- Complexity – These systems, from the data analysis and design phase through implementation, require a vast amount of resources, know-how, skills, time and effort

- Developing a customized design – Automated systems lack standardization. The average time it takes to fully develop the system design is 8 – 12 months

- Rigidity – Once built, you can’t easily take down or re-deploy the system

- Lack of modularity and scalability – High upfront investment and limited ability to scale

- High CapEx and upfront investment – The average automated system has an ROI of 7 – 10 years

- Complicated software integration – Software is the heart and brain of any automated system and the integration into a host system is often underestimated, with serious financial and operational consequences

- Proving the value of the business case – It typically takes 2-3 years following deployment to truly prove the value of an automated system

- High service costs – Impacts the OPEX budget

The benefits of automation are undeniable, but the effort it takes to successfully implement an automated system is often underestimated. Business and warehouse operations often learn the hard way. Thankfully, there is an industry trend towards standardization and scalability, with the purpose of simplifying automation.

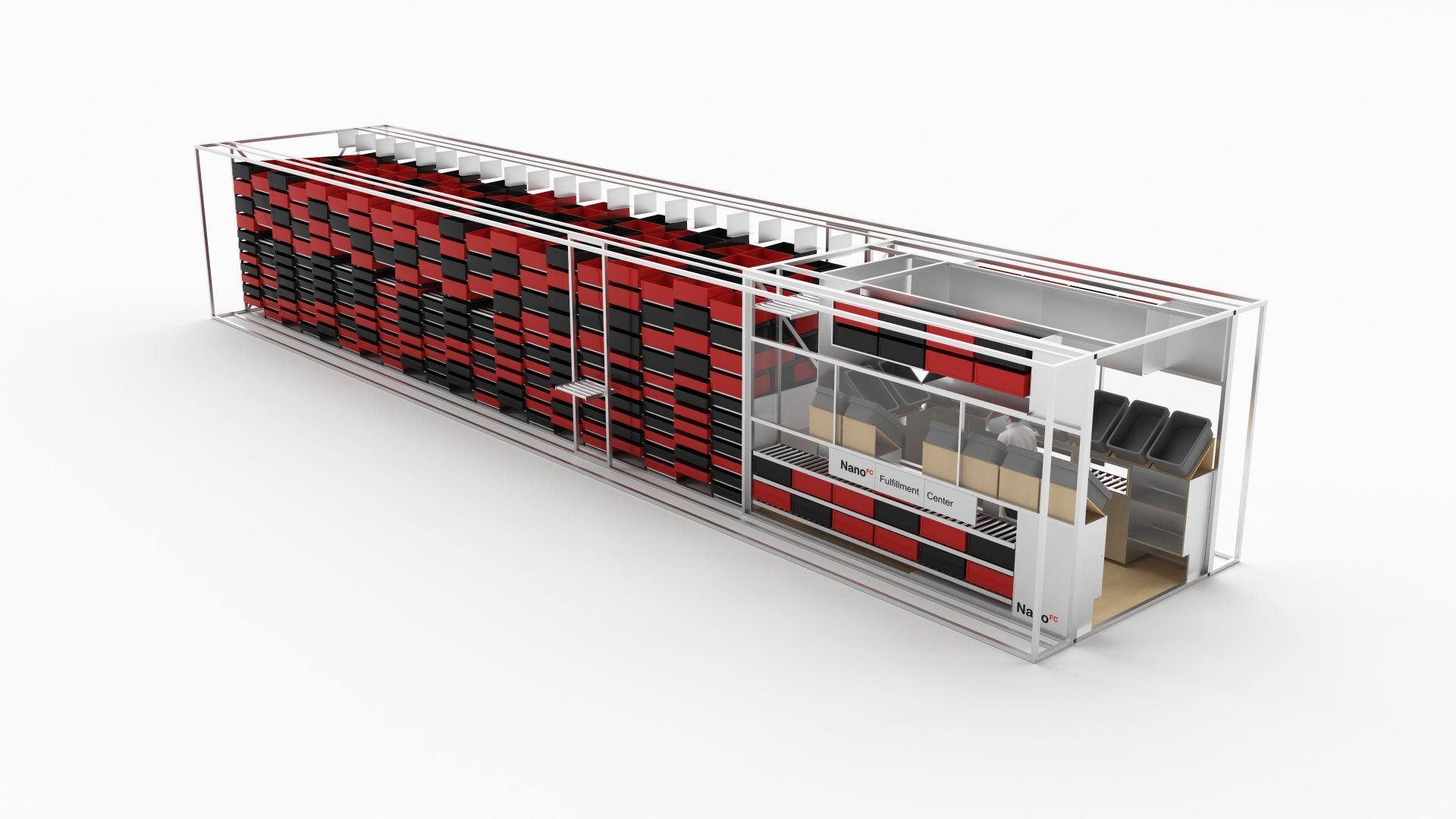

The NanoFC® fulfillment solution was developed with the purpose of targeting and eliminating these known challenges where they were being ignored, Providing automation that complements existing technologies while allowing any company, big or small to offer hyperlocal order fulfillment. The technology is designed to be:

- Re-deployable

- Standardized and pre-engineered – A system that scales with your economic growth

- Simplexity – Removing the complexity

- Affordable technology with a fast ROI, keeping the upfront investment low

- Proving the value of the system within the first few months of deployment

- Low service and maintenance cost

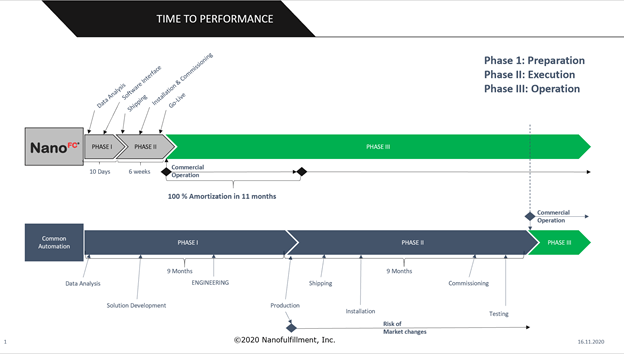

TIME TO PERFORMANCE

The NanoFC® bridges the gap between profitability and complexity. Get your NanoFC® today

#GoNano